In this article, we’ll take you on a journey into the exciting world of Additive Manufacturing, also known as 3D printing. We’ll explore the fundamental principles of this groundbreaking technology, its numerous advantages, and the challenges it presents. From there, we’ll dive into its transformative impact across various industries, including healthcare, automotive, and construction. So, let’s embark on this exploration together and discover how Additive Manufacturing is reshaping the future of product manufacturing and fostering innovation.

What Is Additive Manufacturing?

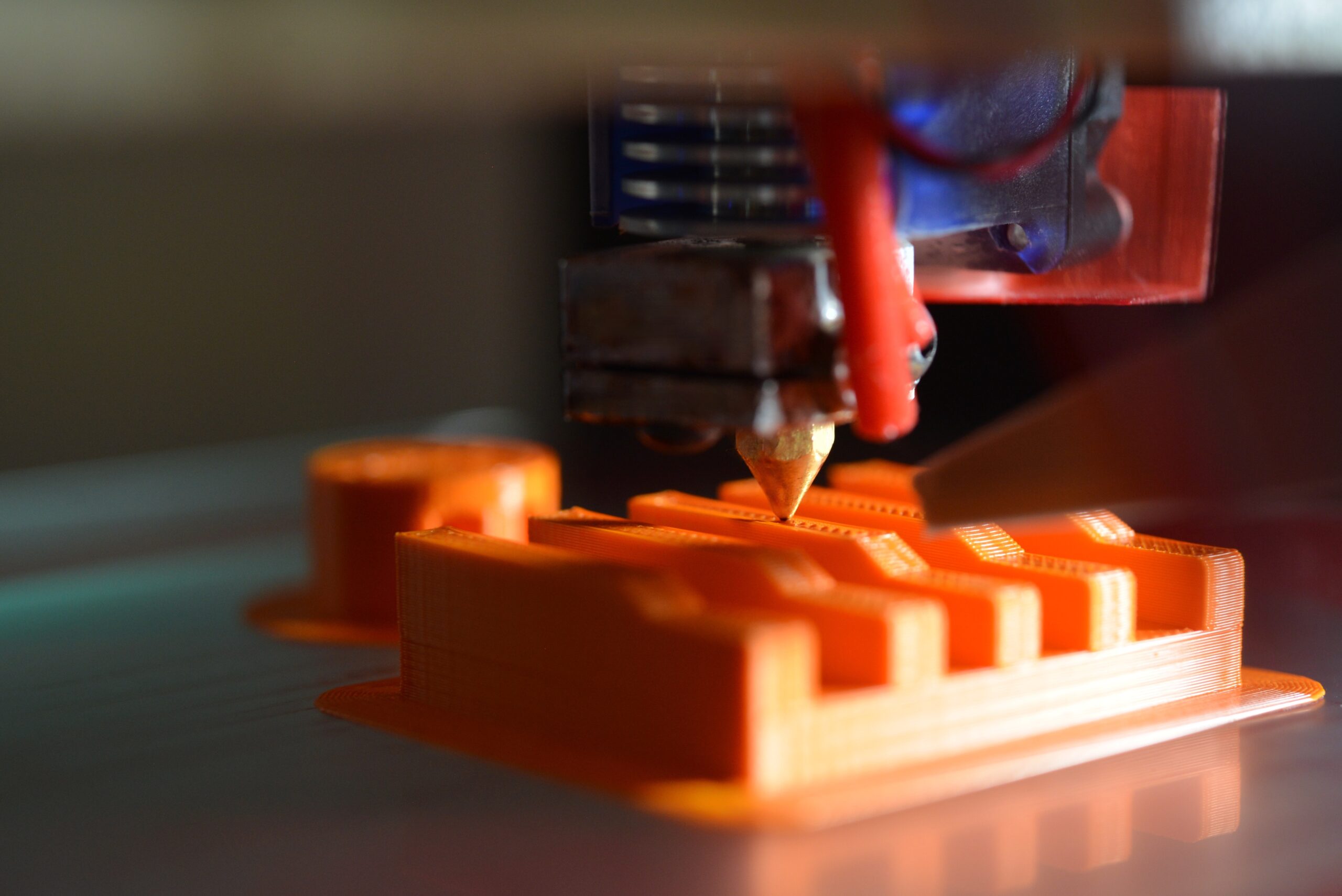

Additive Manufacturing, often referred to as 3D printing, is an innovative technology that allows you to create three-dimensional objects layer by layer. Imagine building a structure by stacking tiny blocks, each one placed precisely where it’s needed. That’s the essence of 3D printing. Instead of removing material (subtractive manufacturing), it adds material to form the final product. This approach opens up a world of possibilities, enabling the creation of intricate designs and complex shapes that traditional manufacturing methods could only dream of.

Why Is Additive Manufacturing So Significant?

Additive Manufacturing is more than just a buzzword; it’s a game-changer. Traditional manufacturing methods often involve wasteful processes where large portions of raw materials are discarded. However, with 3D printing, there’s minimal waste because you only use the exact amount of material required for the product. Additionally, it offers unparalleled design flexibility.

Additive Manufacturing: Basic Principles and Advantages

At the heart of Additive Manufacturing lies a simple yet groundbreaking concept: building objects layer by layer. Think of it as a 3D puzzle, where each piece fits perfectly into place to create a final masterpiece. This is achieved through a computer-aided design (CAD) that guides the 3D printer to deposit material in precise locations. The printer repeats this process layer upon layer until the object is complete. It’s like a robotic sculptor crafting your vision into reality. Now, let’s talk about why Additive Manufacturing is a game-changer:

1. Reduced Material Waste

Unlike traditional manufacturing methods that often involve cutting away excess material, 3D printing adds material exactly where needed. This results in minimal waste, making it an eco-friendly choice. For example, when creating a complex aerospace component, you use just the right amount of material, reducing both cost and environmental impact.

2. Design Flexibility

3D printing lets you unleash your creativity. Whether you’re designing a futuristic piece of jewelry or a functional mechanical part, the possibilities are endless. Intricate geometries, organic shapes, and custom-fit products are all within your reach. Even architects are using 3D printing to construct intricate building facades that would be impossible with traditional methods.

3. Rapid Prototyping

Traditional prototyping can be time-consuming and costly. With 3D printing, you can create prototypes quickly and make modifications on the fly. This agility is a boon for product development, allowing you to iterate and refine your designs faster than ever before.

4. Customization and Personalization

Imagine having a prosthetic limb perfectly tailored to your body or a smartphone case featuring your own unique design. Additive Manufacturing excels at producing customized products. Dental implants, hearing aids, and even footwear can be made to fit an individual’s specific needs.

Challenges and Considerations in Additive Manufacturing

While Additive Manufacturing is indeed groundbreaking, it’s not without its share of challenges and considerations. In this section, we’ll explore the hurdles you might encounter when delving into the world of 3D printing and offer strategies for overcoming them.

Identifying Key Challenges in Implementing Additive Manufacturing

Before we delve into solutions, let’s pinpoint the main challenges:

1. Material Limitations

The materials used in 3D printing can be somewhat limited compared to traditional manufacturing methods. For example, while there’s been significant progress, certain high-stress applications may still require materials that are more readily available in conventional manufacturing.

2. Quality Assurance

Ensuring consistent quality in 3D-printed objects can be a challenge. Variations in layer adhesion, temperature, and printing speed can affect the final product’s strength and durability. Quality control processes and standards are still evolving in the world of Additive Manufacturing.

3. Intellectual Property Concerns

The ease of sharing digital designs in 3D printing has raised intellectual property concerns. Protecting your designs from unauthorized replication can be challenging, and navigating the legal aspects of this technology is an ongoing debate.

Strategies for Mitigating Challenges

Now, let’s talk about strategies to address these challenges:

1. Material Research and Development

To overcome material limitations, invest in research and development to discover or improve materials suitable for your specific application. Collaborate with material scientists and suppliers to find innovative solutions.

2. Quality Control Protocols

Implement rigorous quality control protocols throughout the 3D printing process. Regularly calibrate and maintain your printers, conduct thorough inspections, and invest in training for your staff to ensure consistent and high-quality outputs.

3. Intellectual Property Protection

Safeguard your designs by exploring patents, trademarks, and copyrights. Develop a comprehensive intellectual property strategy that includes monitoring and taking legal action when necessary.

Additive Manufacturing’s Impact Across Industries

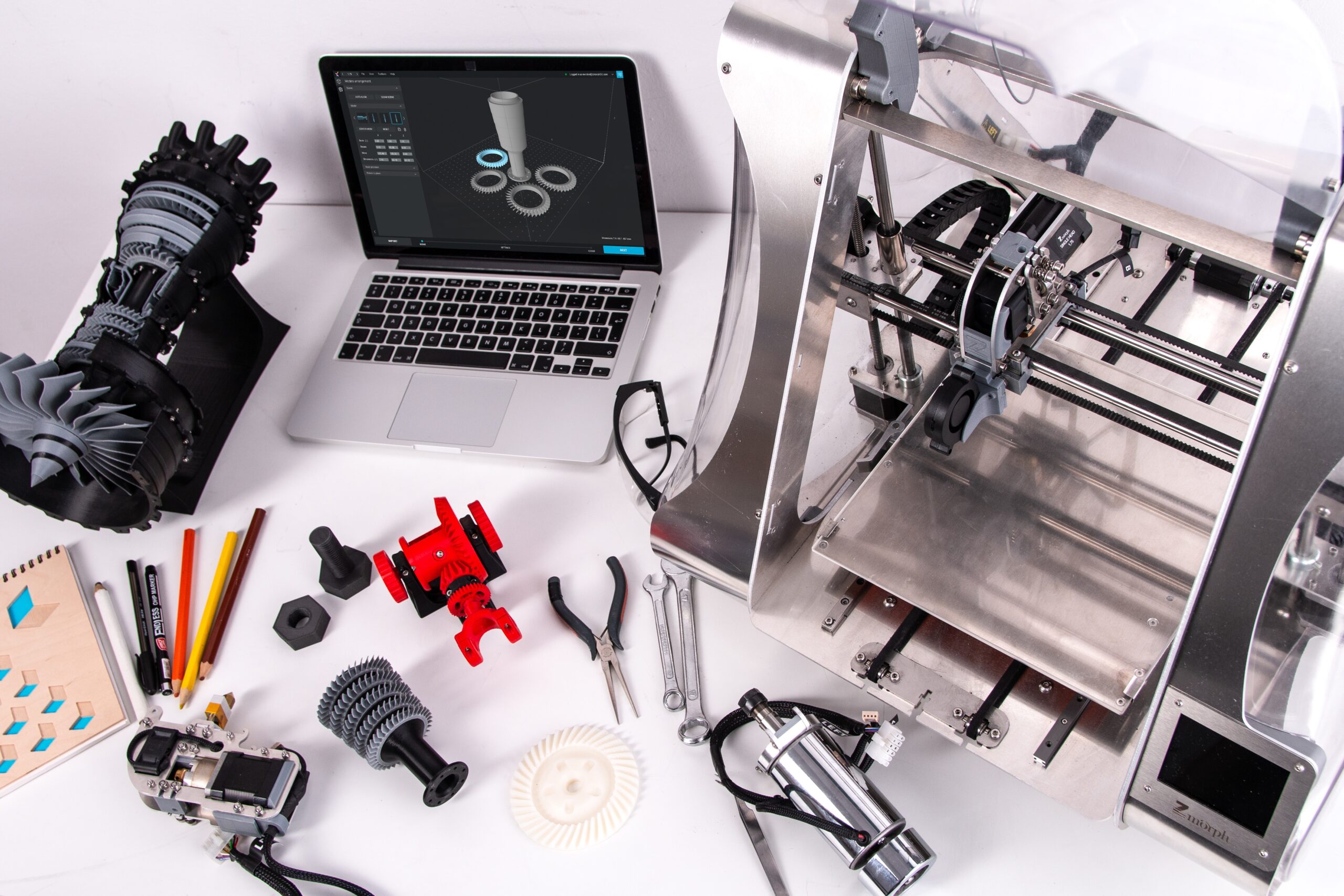

We’ll explore the profound impact of Additive Manufacturing on various industries, uncovering how this innovative technology is revolutionizing the way products are designed and produced.

1. Healthcare Sector

Additive Manufacturing has found a significant foothold in the healthcare sector. For instance, it enables the creation of customized medical implants and prosthetics tailored to individual patients. Doctors and surgeons can now access detailed 3D-printed models of organs or body parts for pre-surgical planning, enhancing precision and reducing surgery time.

2. Automotive Industry

The automotive industry is embracing Additive Manufacturing for a range of applications. From rapid prototyping of vehicle components to producing lightweight and intricate parts that enhance fuel efficiency, 3D printing is transforming the way cars are designed and manufactured. Even customizing car interiors and exteriors is now possible with 3D printing technology.

3. Construction and Architecture

In the construction and architecture sector, Additive Manufacturing has paved the way for groundbreaking innovations. Entire buildings are being 3D printed, offering faster construction times and reduced material waste. Sustainable construction materials, such as 3D-printed concrete, are being developed to enhance durability and environmental friendliness.

By delving into these examples across various industries, we can see how Additive Manufacturing is pushing the boundaries of what’s possible. Its impact is not limited to a single sector, but rather it’s a transformative force driving innovation in countless ways.

Strategic Investment Opportunities in Suryacipta Industrial Area

Suryacipta Industrial Area: Your Gateway to Success

Suryacipta Industrial Area is strategically positioned to cater to the ever-growing demand for innovation in manufacturing. This dynamic location offers an array of benefits that can significantly impact your business.

Advanced Infrastructure

Suryacipta is equipped with cutting-edge infrastructure, setting the stage for efficient and sustainable production processes. From robust utilities to top-notch security, this industrial zone ensures that your business operates smoothly and securely.

Proximity to Key Transport Routes

Suryacipta’s prime location near major transportation routes and logistics hubs streamlines the movement of goods, reducing transportation costs and lead times. Your products can reach both local and global markets with ease.

Unveiling the Strategic Advantages of Suryacipta

Collaborative Ecosystem: Suryacipta fosters collaboration among businesses. Shared spaces, regular networking events, and a community of like-minded innovators create an environment where partnerships, knowledge exchange, and collective growth are encouraged.

Government Support

The Indonesian government provides special incentives and regulations for investors, aiming to facilitate ease in establishing businesses across the country. This emphasis underscores the government’s commitment to creating a conducive environment for business development in Indonesia.

Hub for Technology Development

Suryacipta isn’t just an industrial area; it’s a vibrant hub for technology development. Here, you can tap into a pool of talent, researchers, and educational institutions, promoting innovation and facilitating research and development (R&D) activities.

Embracing Additive Manufacturing in Suryacipta

Suryacipta offers an infrastructure that is both smart and adaptable, capable of supporting tenants in acquiring their 3D printing tools. Moreover, Suryacipta is home to a growing number of tenants who already possess 3D printing capabilities.

In conclusion, Suryacipta Industrial Area stands as a testament to limitless potential, offering businesses a launchpad to achieve remarkable success in Additive Manufacturing and beyond. With its state-of-the-art infrastructure, strategic location, collaborative ecosystem, government support, and emphasis on technology development, Suryacipta is primed to help you realize your vision of the future. As you navigate the ever-evolving landscape of product manufacturing, consider Suryacipta as your partner in innovation and growth.