Required Technology for Smart Factory in Industry 4.0

It may be challenging for a company to reinvent itself into a smart factory but smart manufacturing is the inevitable future because the 4th industrial revolution will demand higher quality production.

To support the statement, in 2019, Deloitte and the Manufacturer’s Alliance for Productivity and Innovation (MAPI) conducted a study on more than 600 companies’ executives to find out the manufacturing labor productivity growth rate from 2019 to 2030.

The result showed significant growth in manufacturing output – up to 12 % – in companies that have used digitally enabled solutions. This means that there’s a promising increase in productivity of a manufacturing company that utilizes technology throughout its production system.

Another research by Gartner in 2020 suggests that 80% of 439 leaders agree that smart manufacturing is an important investment for the future.

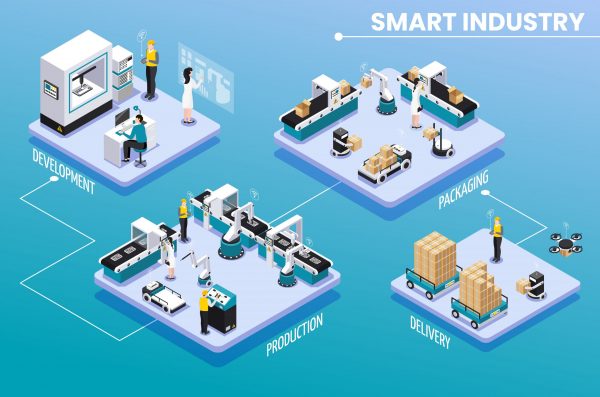

The concept of a smart factory

Smart factory is meant to improve efficiency and deliver cost-effective manufacturing. It has a seamless connection concept for every production stage from planning to implementation.

In industry 4.0, machines and equipment will be able to self-optimize, and each system will continuously collect and share data, while autonomously adapting to the production environment.

What technologies are used in smart factory industry 4.0?

To enable a smart factory, a company needs several essential technologies that will improve the process, including big data analytics, artificial intelligence (AI), the Internet of Things, and cloud computing.

- Big data analytics

One technology that is essential to be a smart factory industry 4.0 is big data analytics. Big data is a technological advance that allows factories to continuously collect and share data in the production systems. It further helps businesses to enhance security, improve supply chain management, optimize storage, avoid financial risks, and more. - Artificial intelligence

Artificial intelligence helps machines to proactively manage and process on its own instead of reactively solving a problem.

With artificial intelligence, machines become smarter and can perform tasks autonomously without human intervention. Using deep machine learning, AI technology can be applied in almost any industrial sector. - Internet of Things

When all devices and machines communicate with each other, the manufacturing process will be fully connected. Using smart sensors, RFID and other devices, the Internet of Things enables factories to be smart in every aspect ranging from inventory to transportation. It also enables companies to quickly adapt to the constant demands and ever-changing marketplace. - Cloud computing

Cloud computing moves the industry forward with its ultra flexible digital storage space. It fulfills the vision of a smart factory because it transforms the way we work and it allows tremendously large amounts of data (apps, programs, tools) to be stored and retrieved virtually, to provide information for users so they can make informed decisions in real time. Cloud-based system is practical and cost-effective as it doesn’t require a company to buy large computers or internet servers.

Smart factory with its digital transfromation can increase efficiencies, reduce costs and improve quality. Whether a company is just starting to run smart or already taking the initiative, smart factory adoption is an investment that will be inevitable for businesses who want to accelerate growth and stand out from their competitors.

Subang Smartpolitan is an integrated township development with a smart and sustainable concept that implement IoT based technology in every aspect. With technology at its core, this evolution enables factory to optimize processes, enhance efficiency, and improve overall performance.The digital integration works to improve the city’s community well-being. In essence, Subang Smartpolitan runs on the concept of industrial revolution 4.0 and its suitable for smart factory.