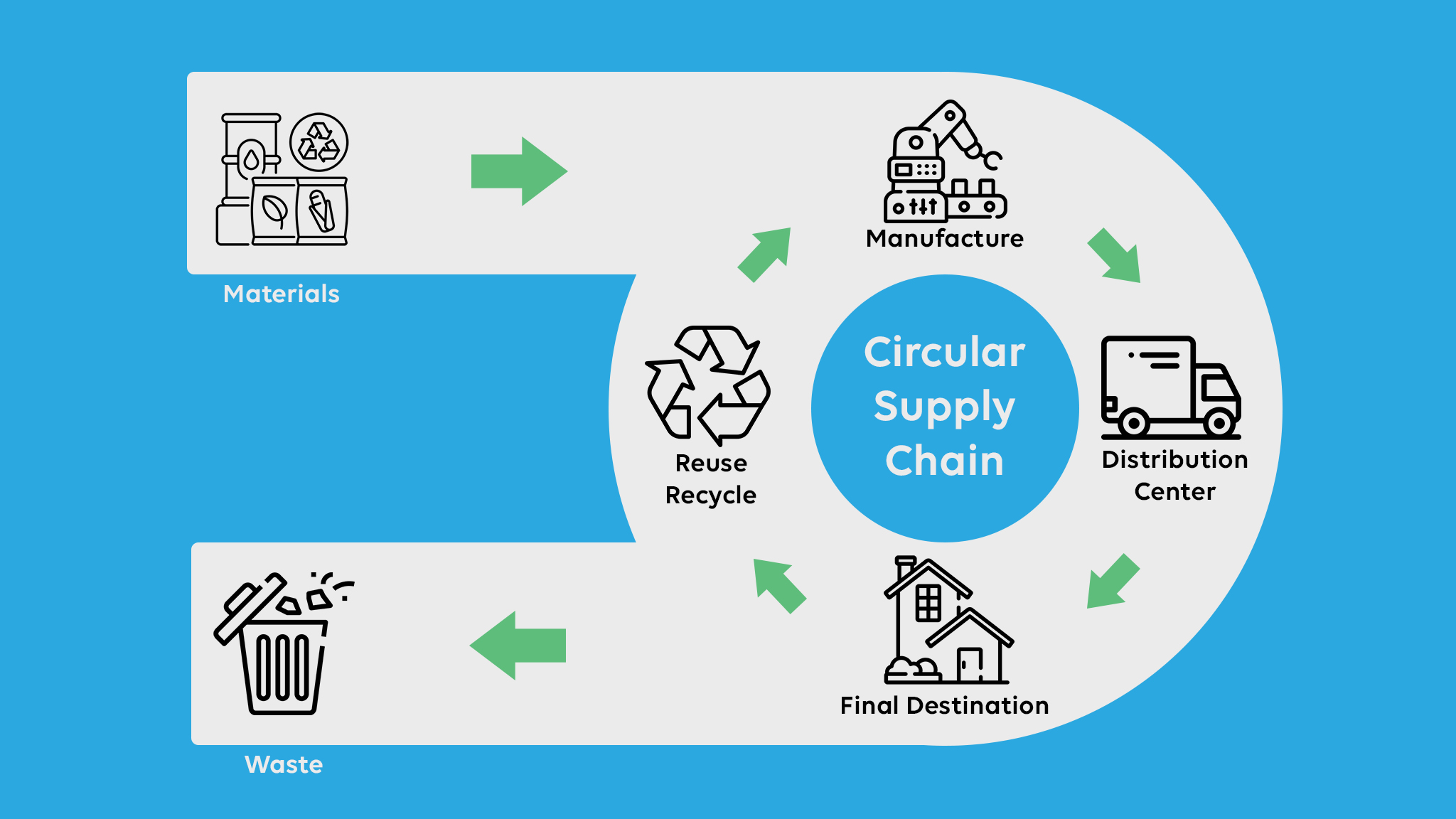

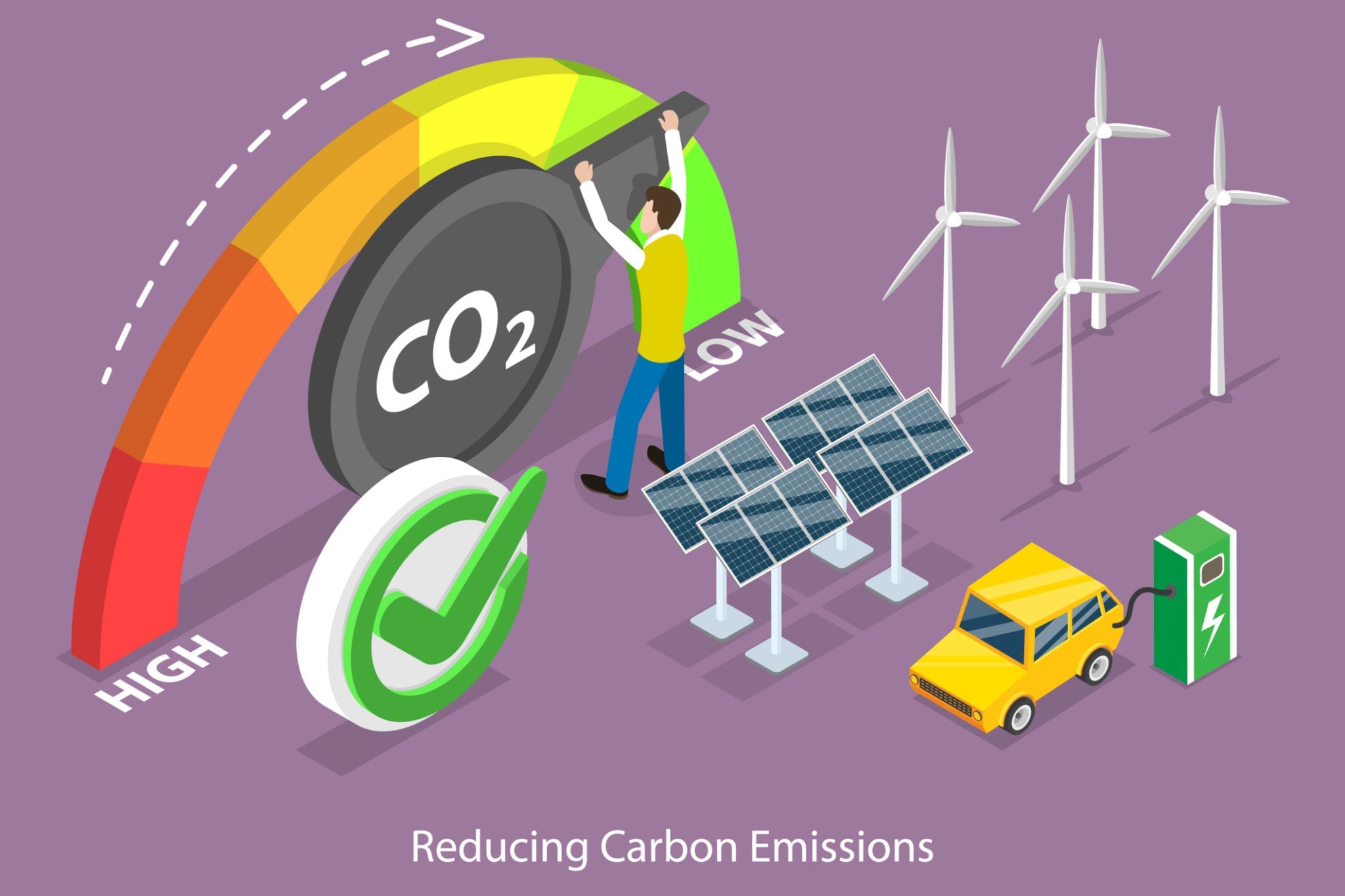

A circular supply chain is an increasingly important concept for the future of businesses worldwide. This concept is part of sustainability initiatives, along with energy efficiency, alternative fuels, net zero emission and optimized routes. The push toward building this concept encourages minimizing or eliminating waste and building a system of continuous resource use.

Circular Supply Chain vs. Linear Supply Chain

A linear supply chain is a common pre existing supply chain method that focuses on gathering raw material, producing it into a usable product, distributing it to the market, and using it until it finishes its usability and then properly disposes.

By contrast, the concept is a new methodology that is greener and more profitable. This method encourages manufacturers of products to utilize unused products and discarded materials and remake them for sale and profit.

Circular Supply Chain Benefits

The circular will replace the linear method, for it brings many benefits, including:

1. Increase Business Value

Reusing parts, materials, and unused products companies maximize profit from the materials they already have. Instead of throwing away the used product as waste, the companies can save money by reducing the overall production cost. At the end of the day, the action will increase the business value.

2. Grow Market Relevancy

The circular is part of the sustainability and “go green” movements. Today’s consumers are more conscious about their shopping decisions, and favor sustainable products over traditional ones. Applying this type of supply chain helps the companies stay relevant to the trend and even grow their market share.

3. Maintaining or Reducing Production Costs

The price of raw materials used in the production process constantly shifts. The price volatility hurts the production budget plan. By using this concept, the companies can anticipate the amount of recycled material that will be used in the new production process, thus keeping the cost at an acceptable level.

4. Keep Up with the Regulations

This concept has become part of the law and regulation in several countries around the world, thus establishing its position as the future of supply chain management. For example, the EU Packaging Directive requires all countries in the EU to recycle up to 50% of the packaging waste. In Japan, the Japanese Recycling Law requires businesses to recycle packaging materials into something reusable. The business’s inability to apply this supply chain concept to the production process means it has less chance of expanding its target market in those countries.

Circular Supply Chain Approaches

There are two main approaches to turning the linear supply chain into a circular:

- Re-use, refurbishing, recycling, and remanufacturing

The main idea is to make the most of a product that has reached the end of its life cycle. It can be done by scraping the needed material for a new production process, reusing the used product and selling it at a discount price, or creating a new product entirely from old materials. - Recirculating the unused product

The term “unused” is different from “used product.” An unused product is not the same as a damaged, incomplete, or inferior product; it simply means that the product was never used. A spare part is the most common unused product. Most companies have unused spare parts that just sit on the shelves and never get into the market. Rather than throwing these items away, the companies can start to take inventory of them and circulate them back into the market.

Allowing materials to retain as much value as possible through the concept is vital to any business and due to the green economy. It allows the business to produce less waste, reduce production costs, and increase customer satisfaction.

Subang Smartpolitan is an integrated township development with a smart and sustainable concept that location in the heart of supply chain link with its strategic transportation access and it supported by smart technology and facilities that suitable for the concept.