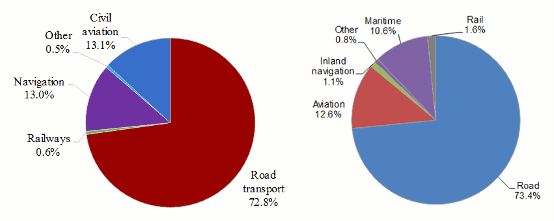

The transportation sector gets a bad rap as one of the main causes of global emissions. Last mile delivery and last-mile logistics are definitely part of this category. Data shows that Europe’s transportation sector is responsible for almost a quarter of the continent’s total emissions.

As the world moves toward a greener lifestyle and trying to lower carbon emissions, manufacturers must also take steps to improve eco-friendly last delivery and logistics. Businesses that take a greener approach are more efficient and have a better brand image, increasing their chances of winning customers’ hearts.

What is the difference between Last Mile Delivery and Last Mile Logistics?

The two terms are basically the same. Its refers to The final step of the delivery process from the distribution hub to the end-user, or the customer’s door. The main goal is to deliver the goods as quickly, accurately, and affordably as possible. Although the name says “last mile,” it actually goes more than that, where it could go up to 50 or 100 miles. The last mile cost could make up 28% of a shipment’s total cost, and that is more than most people think about.

Eco-Friendly Last Mile Logistics and Last Mile Delivery

Here are several strategies for creating a more eco-friendly logistical last mile:

- Take Emission Baseline Inventory

The first step to take is to take inventory of the current emission baseline. To do that, the manufacturer needs to map out the entire information about delivery process, starting with the route, the type of transportation used, the loads on the vehicle, and the type of logistics used during transportation.

From that information, the manufacturer can find information about the CO2 emissions per stop and per route, as well as the non-eco-friendly logistics it used. The baseline information shows the manufacturer’s carbon impact and also lays the groundwork for that. - Route Optimization

The next logical strategy for creating a sustainable last-mile logistics system is route optimization. The manufacturer needs to reconsider the current route and find a way to drive fewer miles. Transportation network structure plays a huge part in this effort, so it will pay off to pay attention to the whole structure to work on route optimization. - Offsetting Emission

Manufacturing industries can collaborate with organizations that specialize in reducing carbon emissions and focusing on sustainability metrics.starting with measuring carbon emissions and their impact, and then working through carbon removal efforts. It can be accomplished in a variety of ways, such as by investing in technology or performing a carbon-offsetting act.for example, planting trees, reforestation, or using solar wind energy. - Customer Transparancy

Introduce the customer into the equation of creating sustainable of last mile. There are several angles to work on. The first one is to inform the customer when the delivery is going to arrive and let them track the delivery process in real time. It helps cut out carbon emissions that come from re-delivery attempts, which are more common that people think of.

The second aspect if about quick delivery. Fast deliveries, such as same-day or next-day deliveries, contribute to traffic congestion and carbon emissions, especially in urban centers. The manufacturers could gives an explanation to the customer about the environmental benefit of slower delivery. This action helps to offset carbon emissions and build customer trust. - 5G and Autonomous Driving

The availability of 5G technology allowed for the development of Connected Automotive Logistics (CAL).The combination of 5G and CAL brought forward the remote control (teleoperation) of autonomous driving. These autonomous capabilities play a part in creating sustainable last-mile logistics and delivery. It helps to reduce costs, shorten stop times, improve driving safety, and boost overall efficiency.

Suryacipta industrial land is ready to host industry 4.0 manufacturing companies around the world, as it is located in the heart of supply chain link with its strategic transportation access and is supported by smart technology and facilities. Subang Smartpolitan offers a sustainable environment with Smart Manufacturing to accommodate major industries. With an integrated management system, the township has utilized a smart environment and facilities necessary to reduce carbon emissions and create a better living.